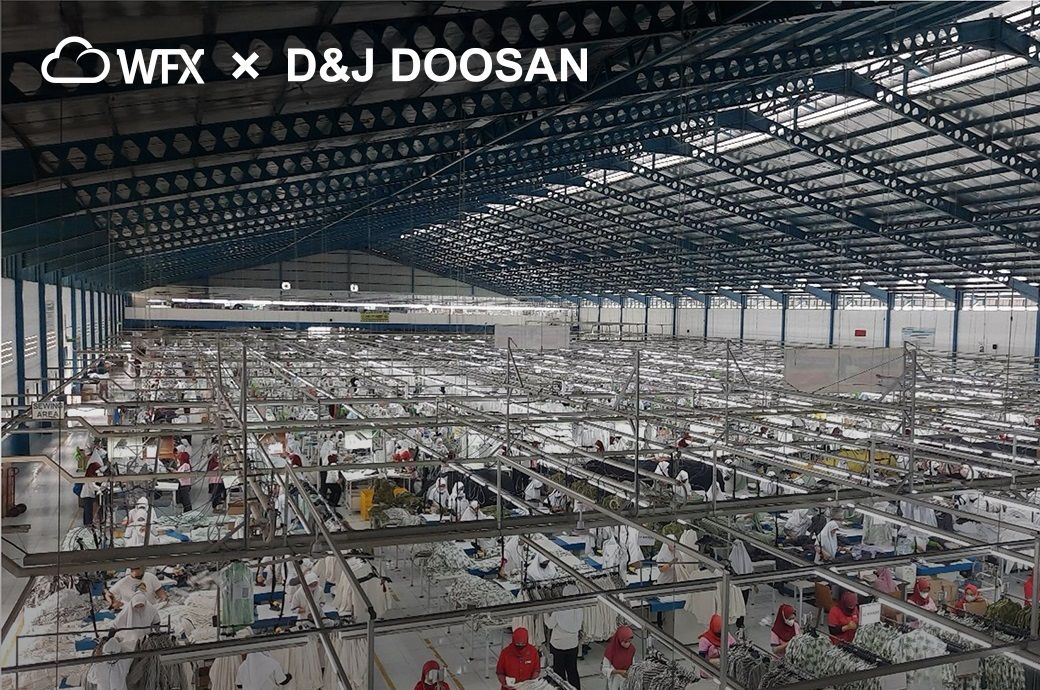

Doosan has partnered with WFX, a leading ERP provider for the textile and apparel industry, to enhance efficiency and visibility in its garment manufacturing operations. The collaboration marks a significant step for Doosan, a 24-year-old company that produces over two million woven garments monthly across its four factories in Indonesia. With major clients such as H&M and Zara, Doosan generates an annual business volume of $100-$140 million. This partnership signals Doosan’s commitment to leveraging advanced technology to maintain its competitive edge in the global market.

Doosan has partnered with WFX, a leading ERP provider for the textile industry, to improve efficiency and visibility in its garment manufacturing.

The collaboration aims to eliminate inefficiencies, enable real-time data access, and drive strategic growth.

WFX’s expertise in apparel manufacturing and tailored solutions are key to Doosan’s global competitiveness.

Addressing Past Challenges

Doosan’s decision to transition to WFX was shaped by a history of ERP challenges that hampered their growth. Previous systems, designed by local Korean providers, failed to scale with Doosan’s operations and lacked the nuanced understanding of the garment industry. These experiences highlighted the critical need for a partner with specialized expertise to navigate the complexities of apparel manufacturing.

Earlier attempts with local Korean systems fell short due to the providers’ lack of industry-specific expertise and the scale of Doosan’s operations. Hyun Cho, general manager, D&J – Doosan explained, “Our first ERP system was too small to handle the complexity and size of our company. The second failure stemmed from the provider’s limited knowledge of the garment manufacturing process, which hindered effective collaboration with our internal teams.”

The repercussions of these missteps were significant. Inefficient processes and limited data accessibility hindered decision-making, with management relying on time-consuming manual reports to monitor operations. Recognizing the urgent need for a robust, specialized solution, Doosan’s leadership prioritized finding a partner with proven expertise in the garment manufacturing sector.

Why WFX?

WFX emerged as the ideal choice for Doosan. Known for its deep specialization in textiles and apparel, WFX’s tailored ERP solutions address the unique challenges of garment manufacturers. With a global team of over 300 experts and a proven track record of working with 600+ fashion customers, WFX brings a wealth of experience and innovation to the table.

The company’s modern, vertically integrated system is designed to digitize the entire fashion production process. Leveraging the latest technologies, WFX offers integrations with all industry tools, in-built industry best practices, AI-enabled automations, and supply chain traceability modules. These features ensure a seamless and efficient approach to managing complex garment manufacturing operations.

Doosan’s team emphasized that WFX’s industry focus was a decisive factor. “We needed a partner who understands the garment industry inside out,” said Dominic Bae, director of operations, D&J – Doosan. “WFX’s experience and their ability to offer data centralization, end-to-end visibility and systemized processes were critical in our decision.”

Goals and Expectations

The partnership aims to address two key priorities: efficiency and visibility. By implementing WFX’s ERP system, Doosan seeks to eliminate the inefficiencies of manual reporting and enable real-time access to operational data. “Visibility is paramount for our management team,” noted Dominic Bae, Director of Operations, D&J – Doosan. “We need on-time data to make informed business decisions. WFX’s solutions promise to streamline this process, empowering us to focus on strategic growth.”

Furthermore, Doosan’s leadership has taken a hands-on approach to ensure the success of this initiative. Unlike previous implementations, which suffered from limited engagement, this project has full top-management involvement. “We’ve learned from past ERP implementation failures,” explained Mr. Cho. “This time, we’re committed to ensuring active participation across all levels of the organization. We understand that more than 60% of an ERP project’s success depends on us, and WFX is the perfect partner for the remaining 40%.”

A Testament to WFX’s Excellence

Doosan’s confidence in WFX extends beyond the software. “From our visit to WFX’s R&D center, it was clear that their team is not only experienced but also deeply understands the garment industry. Their ability to listen and provide thoughtful feedback gives us confidence,” Dominic Bae, Director of Operations, D&J – Doosan said. “We appreciate their thoughtful approach to problem-solving, which focuses on long-term improvements rather than quick fixes.”

Moreover, feedback from WFX’s existing clients highlighted the company’s dedication to fostering long-term partnerships. “The insights we gained from WFX’s customers were invaluable. They’ve been very helpful about what we should be expecting and what we should be aware of going forward.,” remarked Mr. Bae. “Their emphasis on WFX’s professional implementation and investment in continuous system improvements resonated with our goals.”

Driving Innovation in Korean Garment Manufacturing

This partnership not only strengthens Doosan’s operational capabilities but also sets the stage for future growth. With WFX’s support, Doosan aims to enhance its global competitiveness and continue innovating in garment manufacturing, inspiring other businesses in Korea’s textile sector to follow suit.

“We see this as more than a technology upgrade,” stated Dominic Bae, Director of Operations, D&J – Doosan. “It’s a strategic initiative to position ourselves for sustained growth and innovation.”

As the implementation progresses, the collaboration is expected to unlock new efficiencies and insights, reinforcing Doosan’s status as a leading exporter in the global apparel market. For WFX, this partnership underscores its commitment to delivering tailored solutions that drive tangible results for its clients.

WFX’s Ambitious Vision for Korea and Indonesia

With this milestone partnership, WFX is poised to expand its footprint in Korea’s thriving textile and apparel market. Doosan’s adoption of WFX sets a new standard for ERP excellence, highlighting the potential of advanced, vertically integrated systems to transform operations and drive success.

In a dynamic market where precision, efficiency, and adaptability are crucial, the Doosan-WFX collaboration is more than a business success story—it’s a roadmap for other Korean enterprises aspiring to elevate their operations and remain competitive globally.

Note: The headline, insights, and image of this press release may have been refined by the Fibre2Fashion staff; the rest of the content remains unchanged.

Fibre2Fashion News Desk (HU)