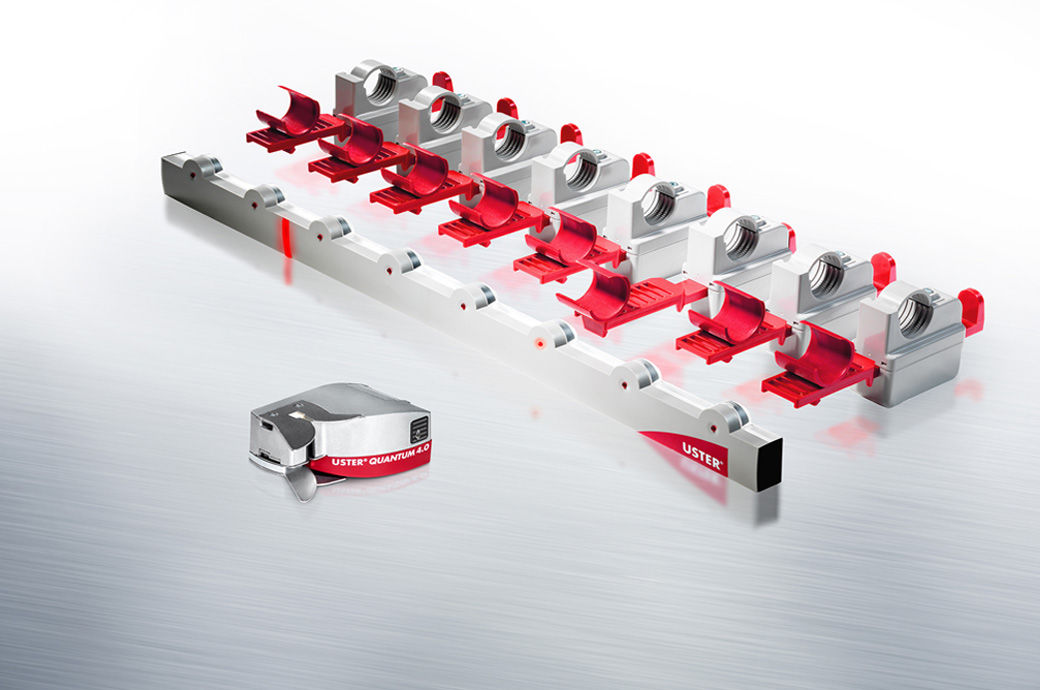

Uster RSO 3D is the intelligent combination of spindle monitoring, yarn clearing and a linked winding machine with spindle identification. This concept shows that even larger customer value can be created from the connection of different process stages and their components, as well as from strategic partnerships among companies.

Uster Technologies has partnered with Pinter Group to enhance preventive quality control in ring spinning.

The collaboration will connect Pinter’s system to Uster’s RSO 3D, a smart combination of spindle monitoring, yarn clearing, and linked winding machine with spindle identification, which optimises process stages and increases profitability.

Uster RSO 3D was introduced in 2019 connecting Uster Sentinel, Uster Quantum 4.0, Muratec QPRO EX/FPRO EX and Spin Inspector to deploy the unique preventive system to stop poor quality being produced. In the meantime, customers have started experiencing the quality and productivity benefits of the system. It was often mentioned by spinners that this is similar to having a Quantum clearer in every ring spinning spindle, the company said in a press release.

Uster Technologies and Pinter Group signed a cooperation agreement that puts profitable spinning as top priority. Both companies are convinced that greater value can be created from combining efforts and solutions. The agreement includes close cooperation and customer support in the field of Ring Spinning Optimisation.

Furthermore, the agreement foresees that the Uster RSO 3D feature will be available for customers using Pinter’s Optifil ring monitoring system in combination with Uster Quantum yarn clearers. This step heralds the era of preventive yarn clearing and expands the RSO 3D benefits to a larger market.

The extended collaboration includes compatibility between Uster Sentinel, Optifil or Pinter’s core yarn attachments using common roving stop equipment and connectivity to the Uster platform. Uster RSO 3D increases profitability with direct process optimisation and traceability from ring spinning to winding. “We believe in creating an open ecosystem to allow smooth interconnection among different process phases,” says Davide Maccabruni, CEO, Uster Technologies. “The cooperation between Uster Technologies and Pinter is based on the joint conviction to create best customer value”.

Fibre2Fashion News Desk (RR)